Rodmaker Profile: Bill Fink

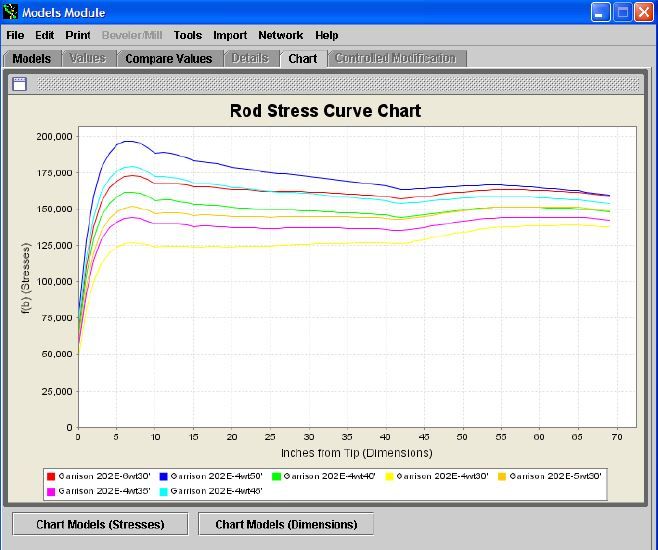

Bill Fink began building bamboo fly rods in the early 1960’s. At the time, he could already claim 25 years experience as a fly fisherman, and was also an accomplished water fowler and upland bird hunter. Bill worked for RCA as an engineer at the time, and wanted the challenge of seeing if cane rods could be improved by the use of modern building techniques, and scientific analysis of the rod tapers. Bill credits the books...

Hex Hits Grayrock: Grayrock 2006

Depending on how you read this story’s title, a couple conclusions can be drawn. Some see “Hex Hits Grayrock” and immediately call to mind the Bamboo Gathering held this summer in Michigan. Others fondly reminisce of the prolific Hexagenia hatch found on certain Michigan rivers, such as the Manistee and Au Sable. A few lucky people, including myself, were fortunate enough...

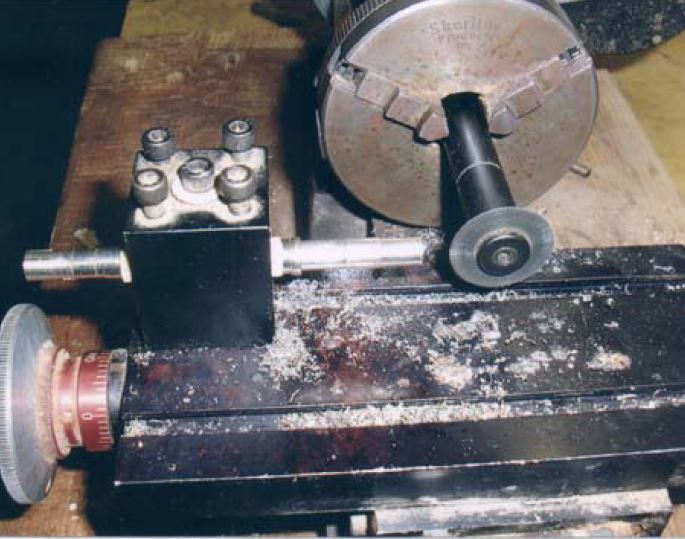

Ferrule Making with Nickel/Silver Tube

Making ferrules from nickel silver tubing consists of basically three steps. First, make the female ferrule. Second, make two male ferrules and third, lap the males to fit the female. The female ferrule consists of a male ferrule soldered into a sleeve to accept another male ferrule and a welt soldered onto the sleeve of the female to reinforce the end of the female ferrule. It is a relatively simple process and, except for the shortage of nickel silver tube, should be considered by all rodmakers who have access to a lathe. Other than the self-gratification of making most of the parts on your rods, the benefit..