Is Node Work the “Speed Bump” in Your Rodmaking

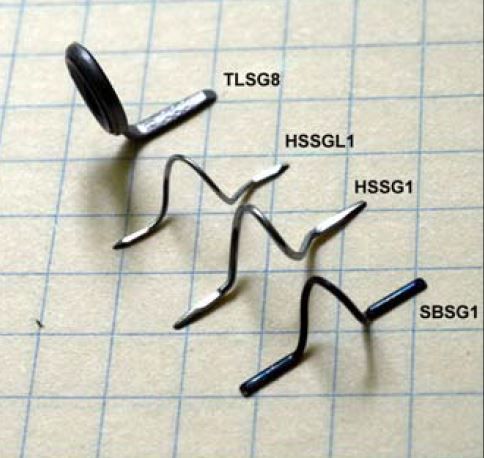

Of all of the steps in the making of a bamboo fly rod, the node work has to be my least favorite. With those pesky humps, kinks, doglegs, dips and lips, nodes can cost us a large investment of time. To straighten them out, rod makers use a variety of different tricks: heat, hand pressure, a vise and some compression. In short, we do whatever it takes....

The Saga of a Para 15

I met George Aldrich on the Rodmakers list in about 1999. We had a mutual interest in model airplane engines. I had a number of them at the time. These were old spark plug gas engines. George was in the business of building the engines. We kind of bonded with this interest. George also had a real interest in Paul Young's rods and owned several of the original Young Rods, but he did not have a Para 15 and wanted to have one. I told him if he could get up here.....

Engraving a Reel Seat

There's not much that hasn't been said well (and often) when it comes to rodmaking, so I thought I'd share something unique to my own process. I recently completed a custom rod with some pretty high end details, and thought I'd share my process as I'm finishing up the engraving of the reel seat.

For me, the creative process begins on paper. A few quick and dirty sketches...